Welcome To The Official Website Of Shandong Aohuang Bearing Technology Co., Ltd

Email:ll@ahfbearing.com

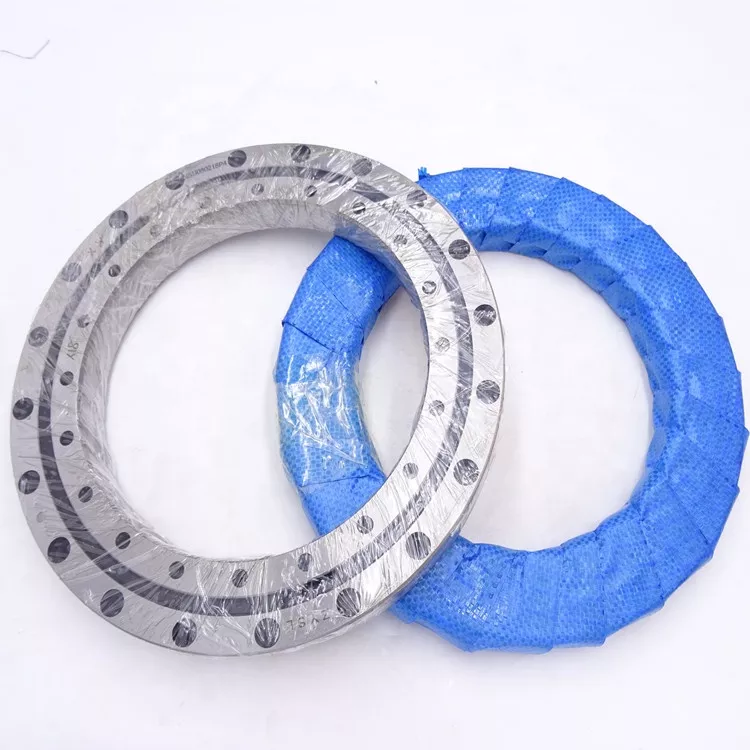

Crossed Roller Bearings

Category:

Thin Section Bearings

Key words:

Rod End Bearing

Email:

WhatsApp:

Crossed Roller Bearings

Description:

Crossed Roller Bearing is a bearing with compact structure in which the rollers are arranged so that they cross between the inner ring and the outer ring. Since the rolling surface is line contact, elastic displacement based on bearing load is extremely minimal, and in addition, it is able to receive complicated loads consisting of radial load, axial load, and moment at the same time.

Rotation accuracy

The spacer retainer fitting among cross-arrayed rollers prevents rollers from skewing and the rotation torque from increasing due to friction between rollers. Unlike conventional types using steel sheet retainers, the crossed roller bearingdoes not cause displacement or locking of rollers and provides a stable rotation torque. Since the inner and outer rings are designed to be separable, the bearing clearance can be adjusted. In addition, highly accurate rotary motion is ensured through adjusting the bearing clearance to provide a preload.

Application:

This bearing is broadly used in revolving parts that require compactness, high rigidity, and revolution accuracy such as industrial robots, machine tools, and medical equipment.

Parameters:

|

Product name |

Crossed Roller Bearings |

|

Material |

Bearing steel GCR15 |

|

Cage |

Brass, steel, Nylon |

|

Lubrication |

Oil Grease |

|

Vibration |

V1 V2 V3 V4 |

|

Application |

Machinery,Automotive, electrical |

|

Service |

OEM Accept |

|

Package |

Netural package or according to requirememt |

|

Sample time |

3--5 days |

|

Production time |

It depends on the quantity |

Our company sells various types and sizes of bearings. Since some products are not displayed here, if you cannot find the product you want on our website, please contact us to make your request, and we will provide you with a good quotation ,thanks!

Applications:

This bearing is broadly used in revolving parts that require compactness, high rigidity, and revolution accuracy such as industrial robots, machine tools, and medical equipment.

Production Process:

Quality Control:

1. Technicians self-check in production

2. Engineer spot check in production

3. QC inspects after mass production finished

4. International sales who were trained the technical know-how spot check before shipping.

Packaging and Delivery:

Packing Details :1. Industry packing

2. Special packing as your requirements

Delivery Details : 1.Express:DHL EMS UPS TNT Fedex

2. By air

3. By sea

FAQ:

1.Your factory how to control the quality?

A: All bearing parts before the production and the production process, strict inspection by 100%, including crack detection, roundness, hardness, roughness, and the geometry size, all bearing meet ISO international standard.

2.Can you tell me the bearing material?

A: We have chrome steel GCR15, stainless steel, ceramics and other materials.

3.How long is your delivery time?

A: If the goods are in stock, usually 5 to 10 days, if the goods are no stock for 15 to 20 days, according to the quantity to determine the time.

4.OEM and custom you can receive?

A: Yes, accept OEM, can also be customized according to samples or drawings for you.

Message

Related Products